Choose a different region to see content for your location

Sustainability at Schweiter Technologies

Schweiter Technologies with its 3A Composites business stands for a sustainable future. The corporation thus aims at a holistic sustainability strategy.

More information

At 3A Composites, we are continuously looking for ways to reduce our environmental impact – so you can focus on your business priorities without compromising sustainability. The ever-increasing demand for resources means it is crucial that we find ways to reduce waste and reuse what is already available. That is why sustainability is a key priority in our new corporate strategy:

Vision

As a team we create and offer products and functional solutions which make the world safer, more beautiful and more sustainable.

Mission

We develop, produce and promote high quality polymer sheets, light-weight paper boards and aluminium composite materials. By 2035, the manufacture of our products will be carbon neutral, 100% recyclable and will provide solutions with a minimal environmental footprint.

In agreement with our management, we have defined four fields of action to bring our mission to life.

Fields of action

Reducing our carbon footprint

Achieving carbon neutrality is an incredibly ambitious goal. This means that we are continuously working to reduce emissions in all areas of our business activities as well as along our value chain.

Developing sustainable & innovative products

At 3A Composites, our special focus has always been on “research & development”. Our engineers are passionate about making existing products better or creating new products that offer our customers greater benefits in terms of quality, functionality, processing, environmental impact and life cycle.

Advancing circular economy

In terms of sustainability, one of the most important aspects is contributing to environmental protection by saving valuable raw materials and avoiding waste. In addition to pre-consumer recycling, which is practiced in our sites, we want to enable options for recycling the panels after they have been in use.

Forstering profitable growth with customers and employees

Our focus is firmly on our customers and their needs. In the process of working towards the best possible products and first rate solutions for their applications, we are able to innovate and break new ground together. The great dedication and passion which our employees invest in their work form the basis of this success.

Environmental Product Declaration (EPD)

ALUCOBOND® has an environmental product declaration (EPD) according to international ISO standards. The “ecological footprint” is examined by an independent third party. The EPD provides information on the environmental impact and environmental implications of the product, such as energy consumption, greenhouse gas emissions (CO2) or water consumption. The document serves as proof for the sustainability certification of buildings.

The EPD for ALUCOBOND® composite panels can be downloaded from here.

To evaluate the sustainability of a building, you need comprehensive information about the building products used. Environmental product declarations (EPDs) have been developed so that architects and specialist planners receive this information in a clear format.

They provide all the important information – such as the life cycle assessment (LCA) results – for an ecological evaluation at the building level. Besides this, they also contain additional information regarding use (for instance about the release of volatile organic compounds (VOCs) during use) as well as details on durability and recoverability.

Environmental product declarations also serve as a basis for the sustainability certification of buildings. Thanks to holistic evaluation procedures, it is nowadays possible to analyse a building with regard to its sustainable quality.

Life cycle assessments (LCA)

An LCA demonstrates the environmental impacts resulting from the construction, use and demolition of a building. The calculation can determine how much energy is necessary to produce the building materials used and to operate the building over its expected useful life. Among other things, the life cycle assessment results are published in environmental product declarations. If no manufacturer-specific EPDs are available, the ökobau.dat database is used as a reference for the LCA of a building. This comprises average life cycle assessment data for many construction products.

In view of the increasing demand for aluminium construction products, the European Aluminium Association decided to develop environmental product declarations (EPDs) in accordance with the international ISO standard. The EPD is regarded as a comprehensive and transparent source of information on the markets. Among other things, it serves as a source of data on which building certifications (such as the DGNB certificate) are based. The assessment covers the entire life cycle of the product, i.e. a large amount of ecological data is processed and presented in an internationally recognised format. It includes information on the “use of primary energy”, “water consumption”, “greenhouse gas emissions”, etc., which are presented together in a set of internationally accepted indicators using units such as the CO2 equivalent. The assessment is additionally reviewed by an independent third party.

ECO-Platform

The ECO Platform’s aim is to develop verified environmental information regarding construction products, in particular EPDs (Environmental Product Declarations). The added value of EPDs under (as part of) the ECO Platform framework is the benefit of being able to use these declarations not only in all European markets but also in international ones.

ECO Platform EPDs are supported by the most important programme operators in Europe such as HQE/INIES (France), IBU (Germany) or BRE Global (UK) and their quality and international acceptance is guaranteed.

Environmental Product Declarations have proved to be the most reliable source of environmental information about construction products. ECO Platform EPDs provide the required information in a standardised format and in line with common methodology and regulations.

The ECO-Platform EPD for aluminium composite material can be downloaded here.

Recycling & VOC Rating

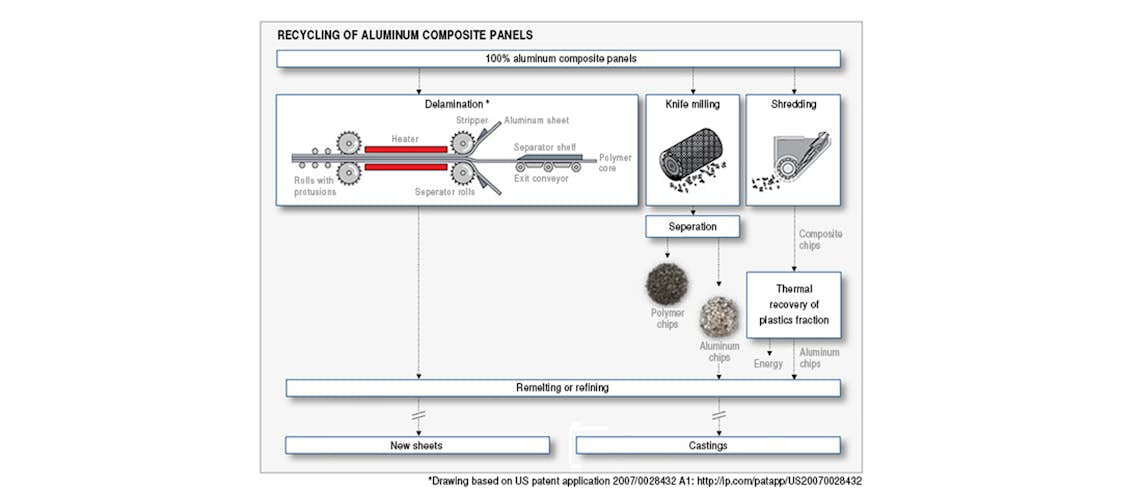

ALUCOBOND® is fully recyclable, i.e. the core material and the aluminum skins can be returned to the material cycle and reused for the production of new material. For example, knife milling can be used to separate the composite panels into the different individual components.

The high intrinsic value of aluminum is a major economic incentive for its recycling. In fact, aluminum scrap can be repeatedly recycled without lessening its value or diminishing its properties. In addition, the energy used in recycling is a mere fraction of primary production requirements, often as little as 5%, yielding obvious ecological benefits.

Lower energy consumption thanks to a sandwich concept

The proportion of aluminium used in the production of ALUCOBOND® is much lower than that of solid sheet. This significantly reduces energy consumption for the production of one square metre without sacrificing stiffness.

Reduction of CO2 emissions

In the production of ALUCOBOND®, we have made great efforts to reduce our CO2 emissions. The first initiative we implemented was aimed at minimising CO2 emissions in the supply chain of the core material used for ALUCOBOND® PLUS and ALUCOBOND® A2. By changing the means of transport from truck to rail, we were able to reduce the distance travelled by trucks by 54%, which corresponds to a 17% reduction in CO2 emissions for ALUCOBOND® deliveries.

Coil coating

We are a member of the European Coil Coating Association (ECCA) and a leader in coil coating standards and emission control. In the coil coating process, 99% of all volatile organic compounds (VOCs) are captured. The coil coating of ALUCOBOND® composite panels is therefore ecologically sound and safe. This is certified by the VOC classification A+. The manufacturing process complies with the strict European and German regulations of Directive 2010/75/EU (Industrial Emissions, IE Directive, comprising the German Solvent Ordinance (31. BImSchV)).

Excess paint is recovered during the process and not incinerated as waste; all solvents used to clean the machines are collected and recycled.